Alumaflex thermal multi-foil insulation, for walls and roofs. Easy to install, great for timber frame, loft and barn conversions

Multi Foils in Reducing Energy Costs

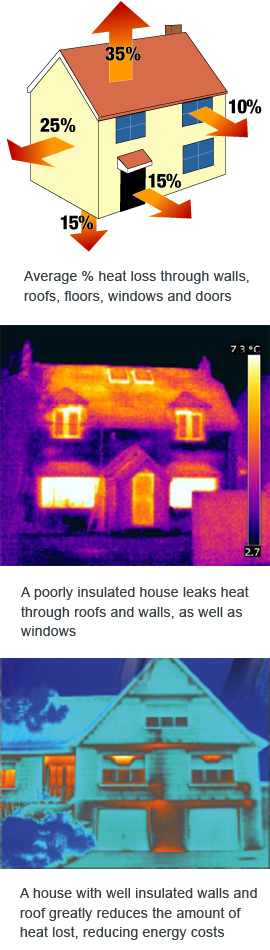

To provide a quick snapshot, 85% of housing built before 1965 in the 15 core EU states have no thermal insulation and only about 50% of dwellings in these countries have any form of thermal insulation so there is plenty of scope for reducing emissions and energy consumption. In the UK current thermal transmittance targets are set out in the 2010 Building Regulations and they continue to drive down target U-Values in new- build and refurbishment.

How do homeowners and specifiers make sure they continue to meet the targets outlined ?

The specification of the insulation performance standard and the design solutions adopted are critical decisions that will have a long-term impact on the performance of a building. There are several types of materials available to specify and introduce into the building fabric to reduce heat loss. All of these materials will have a level of impact but it is important to understand that these could be significantly degraded by the quality of the installation or by the long-term performance of the material in situ.

The specification of the insulation performance standard and the design solutions adopted are critical decisions that will have a long-term impact on the performance of a building. There are several types of materials available to specify and introduce into the building fabric to reduce heat loss. All of these materials will have a level of impact but it is important to understand that these could be significantly degraded by the quality of the installation or by the long-term performance of the material in situ.

Alumaflex Thermal insulation is specified to control three components of heat transmittance through the building fabric:

- Conduction of heat through building fabric.

- Convection via air movement.

- Radiant transmission.

Criteria for specifying Alumaflex thermal insulation.

- Performance in use and longevity – full product certification

- Buildability and the reassurance that on-site work will meet the required thermal design standards.

- Will the insulation have minimal impact on building design and capital cost.

Buildability – Consideration should be given to the following design issues when considering insulation materials:

- Detailing required to achieve thermal integrity, including avoidance of cold bridges, air-flow paths, opportunities for settlement or compression of fill and other movement during and after construction.

- Ease of working around complex details on site.

- Health and safety considerations for the installer.

- Ease of testing.

- Do the materials meet the necessary test criteria under the Building regulations.

- Requirements for vapour and radiant barriers to maintain performance.

- Ability to undertake additional work without significant disturbance to the insulation materials.

Alumaflex: Impact on building design

- The insulation material and effect on floors and external wall thickness are minimal.

- Multi-Foil Insulation provides the opportunity to incorporate the insulation into other aspects of building function; for example, creating thermal benefits in limited spaces eg. the use of a roof void as a habitable space.

- Alumaflex provides significant thermal benefit with a low level of capital cost.

The Passivhaus Concept : Current and Future Building Regulations with Alumaflex Insulation

The key to devising an economical, low-energy design solution based on a passive model is in providing sufficient insulation and thermal mass. This eliminates the requirement for a heating system, offsetting the costs of additional insulation against the savings in building services.

High levels of insulation and air-tightness are an absolutely critical element of the low-energy, “Passivhaus” concept. the Passivhaus concept of low zero-carbon housing, is driven by the concept of super insulation, minimal air infiltration, carefully controlled solar gain and use of high levels of energy recovery to minimise requirements for space heating.

Alumaflex used in conjunction with other forms of mass insulation can help designers to achieve this target and the passivhaus concept can be realised.

This approach will take building in the UK and other countries to the necessary targets in current and future building regulations. Just as important is the need to address current housing stock.